We're back with a new look, courtesy of Blender and the Freestyle renderer. I hope you like it. Personally, I'm satisfied with the "technical illustration" appearance of the 3D renderings , but I'm not so happy with the 2D drafting work flow and results and am considering moving away from Blender to a 2D CAD program for those.

We are going to look at a carpentry model that would have been used to teach roofing layout principles to apprentices and young carpenters. Today,

aspirants and apprentices spend two hours a day in night school where study of these kinds of models still figures heavily. The model is not to scale and is missing common rafters, but it has features that appear in almost all roofs in the French tradition: principal and half rafters, hip rafters that are backed to meet the slope of their adjoining surfaces, and purlins that are supported by the principal and hip rafters. As we discussed in my last post, the surfaces of the different rafters lie on imaginary solids that are similar to the overal roof shape. This isn't always the case, but it is a guiding principle in the layout. This model even has moving parts, to illustrate the drafting construction for finding the hip rafter section:

We begin the plan by laying out the shape of the roof and the principal rafters:

The "roof" is 64 x 102 centimeters, with a center height of 36.8 cm. The kingpost is 6.2cm x 6.8cm. Note that this shape is not similar to the rectangle of the whole roof. Therefore ridge lines don't meet the corners of the kingpost, giving its top a kind of funky truncated pyramid shape.

The principal rafters are 2.8cm wide. The top surface of the principal rafter lies 6.8 cm vertically below the roof surface. The bottom surface is 11.4745cm below the roof. There's no reason for that bizzare dimension, but I forget how I originally sized the rafter! In the drawing, the elevation view of the rafters is placed on top of a plan of half the roof. The cursive "N" stands for niveau or level. This indicates that that line is at the reference ground level of the whole plan.

Next, it is straightforward to construct the elevation view of the half rafters:

The roof line and half rafter surfaces must intersect the principal surfaces at the center line of the king post. So, the intersections in the principal elevation view can be "swung down" with a compass to construct the other elevation; the half-rafter is then constructed parallel to the roof surface. The rafter footprints are directly constructed from the elevation views and the known width of the rafters. Here's what we have in 3d:

It is easy to see the odd shape of the top of the king post. Also, notice that the half rafter meets the king post at a slightly lower height than the principal rafters; again, this is due to the difference between the king post section and the shape of the whole roof.

The rafters are fixed to the king post with mortise and tenon joints. The layout of these joints is an interesting subproblem. the top of each tenon is horizontal so the rafter can be slid into place, and the bottom must follow the bottom surface of its rafter. The tenons coming in from the four sides of the king post need to meet nicely in the middle.

I've sized the tenon for the half rafter at 0.8cm and given it a "V" shape that follows the ridge lines. The principal rafter tenons are sized proportionally to meet the half rafter tenons at the ridge lines. A portion of the principal rafter tenons is higher than the top of the half rafter tenons, so that is given a rectangular profile to avoid any voids in the middle of the king post:

An interesting result of constructing the tenons this way is that the interior of the mortise has the same shape as the roof:

We now turn our attention to the hip rafters. I'm going to give them the odd width of 5.037cm, for reasons that will soon become apparent. The hip is going to have a pentagonal shape: the top surfaces are aligned with the neighboring roof surfaces, the sides are plumb, and the bottom just touches the intersection of the upper surfaces of the principal and half rafters. The two plumb sides should have the same height, so in plan view the edges between the tops and sides intersect the ground plane on a line perpendicular to the axis of the hip. On the other hand, those edges should intersect the outer edges of the roof surface. How do we place a perpendicular line with the given constraints? The answer is a parallelogram construction:

Two lines of the given length i.e., the desired width of the rafter, are extended from the corner vertex, perpendicular to the ridge line in plan. We extend a line parallel to the left roof edge from the end of the near line, and a parallel to the near roof edge from the end of the far line. These lines' intersections with the roof edge give us the line we are looking for: each of lines with which we started form a parallelogram that includes this new line, so that line must have the same length as the original lines [Edited per Chris' comments]. Lets draw in the rest of the hip:

The inner edge of the hip rafter footprint is perpendicular to the axis of the rafter and meets the intersection of the upper rafter surfaces with the ground plane.

We can see the reason for the odd hip dimension now: the far edge of the hip meets the king post at the intersection of the left and far roof surfaces. We do this in order to give the hip enough width to have visible lip that sits against the near surface of the king post. Of course, this would give us problems if we constructed the far hip rafters, but we are not going to do that. This is not a scale model of a real roof; it only illustrates the layout on one side of a roof. We finish off the hip rafter's footprint by making its inner edge touch the "inner ridge line" formed by the top surfaces of the rafters.

It should be clear that I didn't start the layout of the hip by choosing a random dimension; I worked backwards from the king post and then measured the distance. However, the parallelogram construction for drawing the hip is a common technique, not just in French carpentry drawing but in other traditions as well, and it is important to be exposed to it.

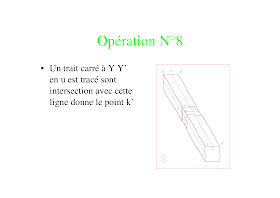

After drawing the plan view of the hip rafter, we can derive the section of the rafter by using the technique in the previous blog entry for the triangular rafter. Draw an elevation view of the top of the hip rafter along its plan view, from point A to F, giving it the height of the king post at K. Choose a point X on the hip rafter and drop a line perpendicular to AK from there. This will be the point that is rotated down to the ground plane to begin the section construction, so we can choose the position of X to place Y, the rotated point, at a convenient location that is neither in the rafter footprint nor too far away in the middle of the drawing. Draw HZ, the intersection of the section plane with the ground. As explained in the last post, lines from Y to H and Z are the adjoining roof surfaces in the section drawing, so those give us the top of the rafter section.

The bottom of the section is found by locating the intersections of the bottom planes of the principal rafters with HZ. In the section view the lines showing these planes are parallel to the lines we already found for the roof surfaces. These new lines meet at U, giving us the bottom of the section.

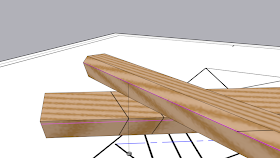

When we turn the hip rafter on its hinge, we see that its cross section does line up with our construction lines, and the bottom of the rafter passes through point U:

The next task is to find the final shape of the hip rafter where it meets the king post and mark the required cuts on a drawing so that a carpenter could cut it out, either by transferring measurements onto the timber or by creating the drawing on the ground and laying the timber on top of it. This implies that we need to make drawings of the hip rafter in its true proportions i.e., with the length, height and width square to our view. The elevation we constructed for finding the hip rafter section is a good start: it shows true length, and we can easily add the height of the hip rafter to the drawing. We will add another view of the rafter from below to show the width.

From our plan and 3d views of the model, we know that the hip rafter wraps around the king post in a kind of ell called a barbe or beard. We can treat the near and right sides of the king post as planes that cut through the hip rafter:

The portion of the hip rafter that needs to be cut away lies on the "inside" of both planes, in a Boolean intersection of the half spaces defined by the planes.

We will proceed by finding the intersections of those planes with the arrises of the hip rafter and then connecting them to form the lines of intersection of the hip rafter and king post surfaces. When these lines are marked out on the real timber, the carpenter can saw along them to establish the needed cuts. Obviously he shouldn't saw all the way through the wood, but it is reasonably straight-forward to saw along both sets of lines until their intersection, and no further.

In the plan view, extend the line of the near (red) king post surface to intersect all the edges of the hip rafter:

The left and right lines of the rafter in plan view represent upper and lower edges of the vertical surfaces of the rafter, so we will need to plot the intersections of each of them with the king post surfaces. There is only one top arris on the rafter, of course. We bring the intersections from the plan view up into the elevation view of the hip rafter, and from there into the rafter's bottom view. (Dashed lines in the rafter views show lines that are hidden by surfaces that are closer to the viewer; for various reasons the dashes may not show up well. I am hoping to fix that in future articles).

The procedure for the right (blue) king post plane is identical:

The joint between the hip rafter and the king post has been completely laid out. If the drawing were done at full scale on the workshop floor or construction site, the timber could be placed on top of e.g., the elevation drawing in order to transfer the intersections in the drawing to the timber. Marks on the right side of the timber can be transferred directly; the other marks need to be brought up the sides of the timber using a square.

Both the drafting and the timber marking methods are called rembarrement. This has nothing to do with rude behavior. The word refers to "pushing back" a point along a line from one context to another. When drafting the hip rafter, we moved the intersection points from plan view, where they were easy to find, into the much more useful elevation view. The carpenter moves marks from the floor up to edges using a square or plumb bob, perhaps making marks on intervening edges. These methods are still in use in carpentry drafting and layout. Rembarrement works well when using the straight and square timber that is easily available today. If we placed the hip rafter timber over its full-scale drawing and found that it was warped or out of square, we could probably fake it: use a corner and edge of the timber as a reference and mark out the lines. However, if the king post timber was out of square we would be kind of stuck. We don't use the real king post to lay out the hip rafter, but an abstraction of its surface planes that are perfectly flat and square. We could proceed by "fixing" those parts of the king post that do intersect with the rafter to be square. As I understand it, this is the "square rule" practice that started appearing in America in the early 18th century.

In Europe, carpenters had been dealing with out-of-square timbers in their carpentry drawings since the 13th century (at least). In the next installment we'll look at the layout method they used and how it is incorporated in the carpentry drawing.